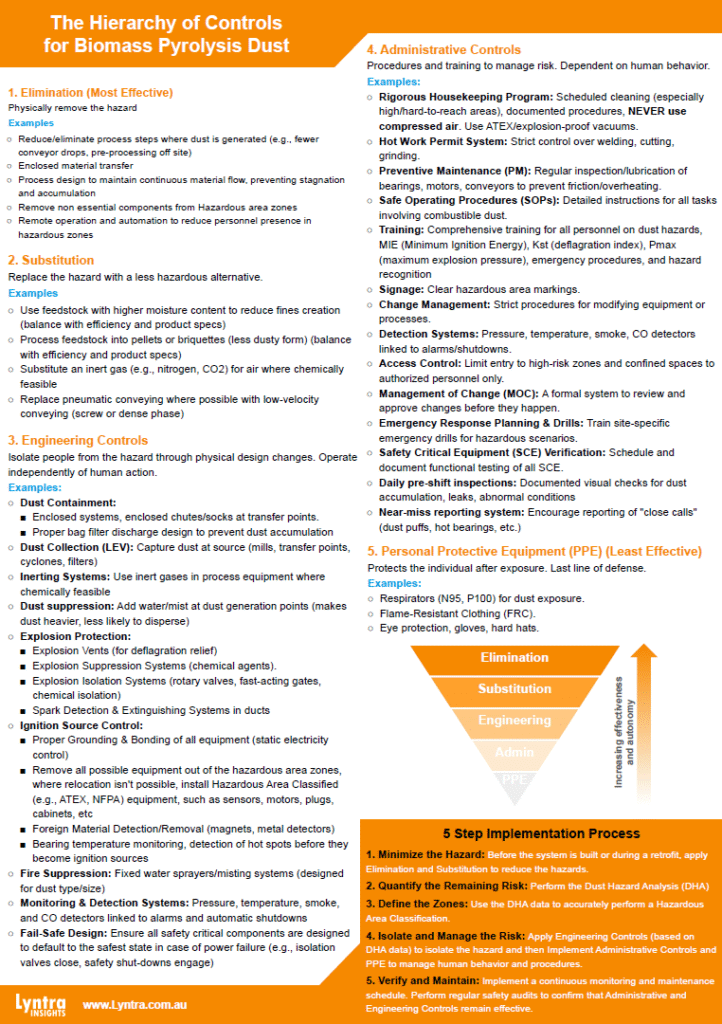

Combustible dust in biochar operations poses serious explosion and fire risks. This guide presents a 5-level framework for managing these hazards, ranked from most to least effective:

1. Elimination (Most Effective) – Remove the hazard entirely through design choices like enclosed material transfer, continuous flow systems, and remote operation that keeps personnel out of hazardous zones.

2. Substitution – Replace hazardous conditions with safer alternatives, such as using pelletized feedstock, inert gases instead of air, or low-velocity conveying systems.

3. Engineering Controls – Isolate people from hazards through physical systems: dust collection at source, explosion vents and suppression systems, proper grounding and bonding, spark detection, and automated monitoring with fail-safe shutdowns.

4. Administrative Controls – Manage risk through procedures and training: rigorous housekeeping programs (never use compressed air), hot work permits, preventive maintenance schedules, comprehensive operator training, and near-miss reporting systems.

5. Personal Protective Equipment (Least Effective) – The last line of defense: respirators, flame-resistant clothing, and eye protection. PPE protects individuals but doesn’t eliminate the hazard.

Implementation Strategy: Start by minimizing hazards through elimination and substitution, conduct a Dust Hazard Analysis (DHA) to quantify remaining risks, define hazardous area zones, apply engineering controls, then layer in administrative procedures and PPE.

The key principle: Controls that don’t depend on human behavior (elimination through engineering) are always more reliable than those that do (administrative and PPE).