Featured Insight

he Biochar market is still quite young, many producers are ahead of the market in their region, I’m starting a new series where we will look at alternative revenue streams (upgrade options) that...

Insights

We often rely on a single Moisture Content (MC) value when prepping biomass. This number, however, masks critical seasonal changes that dictate drying efficiency and final product yields. Optimising...

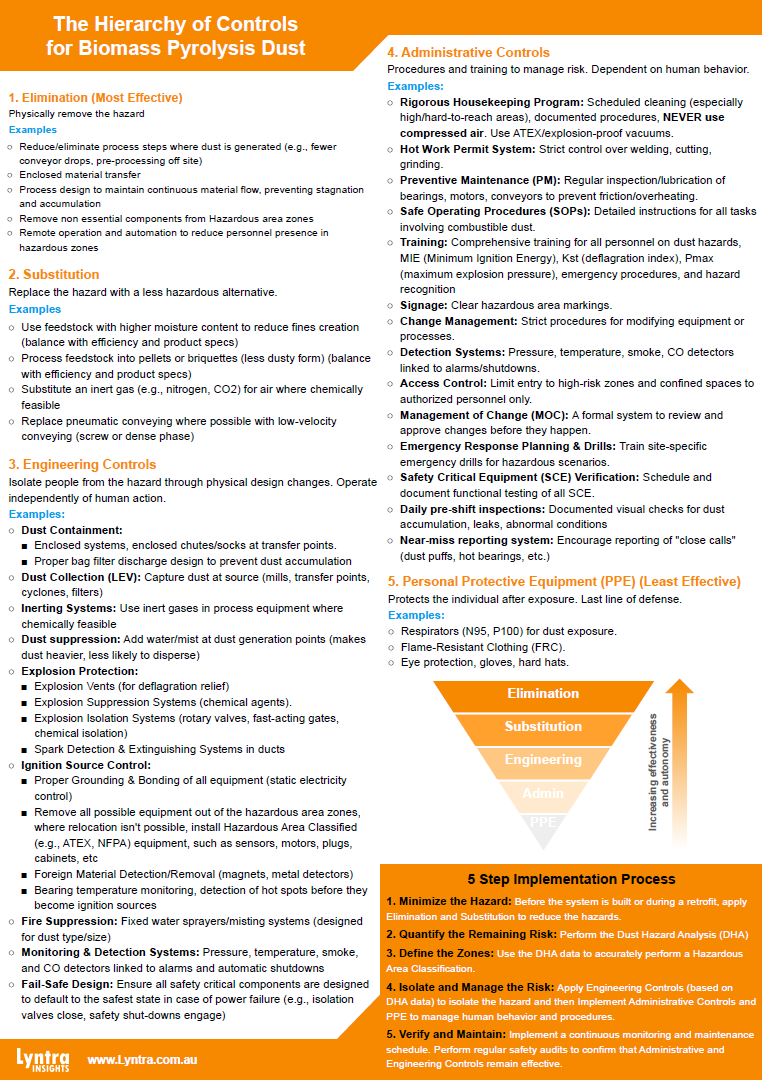

Operating a biomass pyrolysis facility? Use this 25-point checklist to evaluate your current dust explosion prevention controls. This self-assessment covers the hierarchy of controls—from elimination...

Combustible dust in biochar operations poses serious explosion and fire risks. This guide presents a 5-level framework for managing these hazards, ranked from most to least effective: 1. Elimination...

From the science of a dust explosion to the practical controls, we’ve covered a lot. As we close this discussion, here is a final guide for anyone operating a biomass pyrolysis reactor. Remember these...

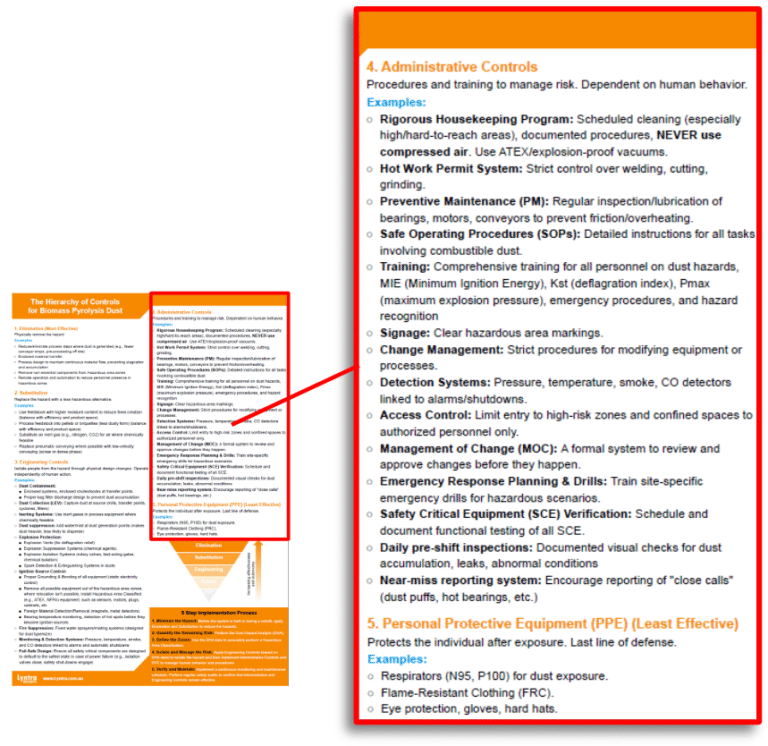

In Part 1, we covered the robust, human-independent controls: Elimination, Substitution, and Engineering. Now, we move to the final two layers of the safety blueprint, the essential, human-driven...

In our last post, we established that biochar presents a greater hazard than its feedstock. Now, let’s explore the most effective framework for managing that risk: The Hierarchy of Controls. This is...

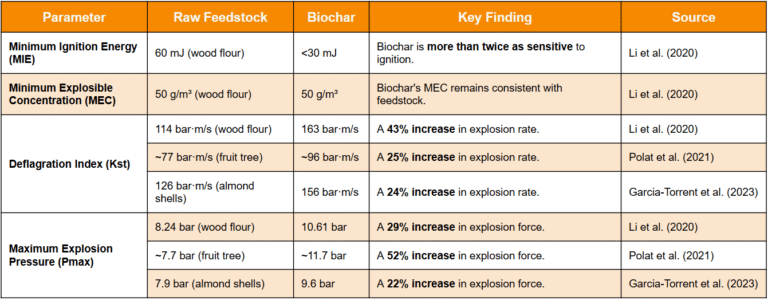

While the combustible nature of biomass dust is well-established, pyrolysis can sometimes increase its explosive properties, something we should keep in mind when doing risk assessments and safety...

“98% of major projects face cost overruns or delays”, today we’ll be looking at what causes these issues and how we can mitigate them...

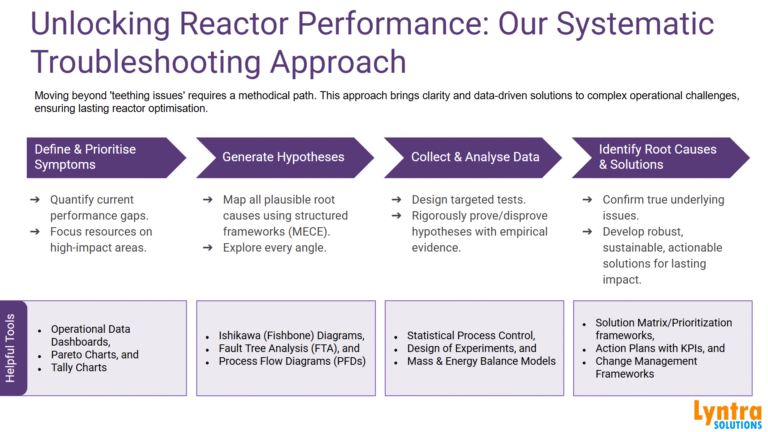

When it comes to newly installed pyrolysis reactors, the journey from commissioning to optimal performance isn’t always a straight line. Sometimes, even with top-tier equipment, we encounter...