“Just dry it more” isn’t the magic solution everyone thinks it is for biomass pyrolysis.

I was reading through some recent research on biomass thermal process optimisation, and it reminded me of a conversation I had last week. They were frustrated because their biochar yields were inconsistent, and their first instinct was to “just dry the feedstock more.”

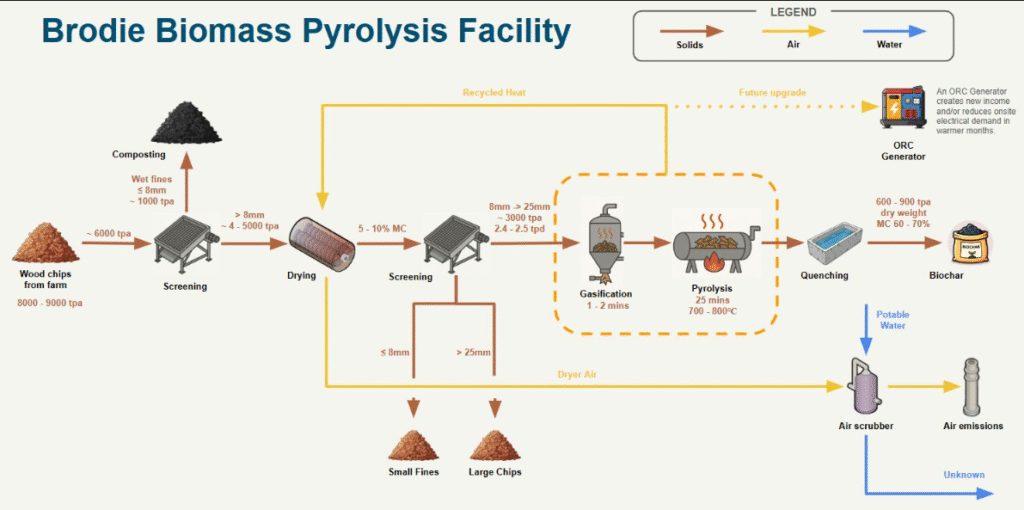

But moisture content is more nuanced than that. Biomass pyrolysis / gasification typically requires moisture content management as a key parameter, not just minimisation.

Here’s what I’ve learned for pyrolysis from recent projects and research:

Too dry (below 5%):

– Dust generation becomes a real safety hazard

– You lose the beneficial steam reformation reactions that actually help crack tars

– Rapid heating can cause thermal shock and particle breakdown

– Higher fire and explosion risks during handling

Too wet (above 20%):

– Massive energy penalty heating all that water before you get to actual pyrolysis

– Steam interferes with the pyrolysis reactions themselves

– Material handling becomes difficult, chances of bridging are increased and the angle of repose can be changed

– Temperature control becomes nearly impossible

– Product quality suffers dramatically

The optimised zone (5-15%):

– Steam assists with tar cracking and improves syngas quality

– Consistent thermal profiles throughout your reactor

– Optimal energy efficiency for the overall process

– Better product consistency across biochar, syngas, and bio-oil

What’s particularly interesting is how this applies across different thermal processes. Whether you’re running pyrolysis, gasification, or even the thermal phases of anaerobic digestion, each has its optimal moisture window.

The above numbers are just rules of thumb, they change depending on your process, feedstock, and desired product mix and specs.

The key insight? Moisture content isn’t just about drying, it’s about optimisation. Sometimes you need to add moisture, sometimes remove it, but always with your end products and process stability in mind.

What moisture control strategies have worked best in your thermal processing experience? I’d love to hear how others are approaching this fundamental parameter.

Beyond “Just Dry It”: The Nuance of Moisture Content in Pyrolysis