When it comes to newly installed pyrolysis reactors, the journey from commissioning to optimal performance isn’t always a straight line. Sometimes, even with top-tier equipment, we encounter those elusive operational challenges that impact everything from yield to product quality.

I’ve been reflecting on why some reactors don’t immediately hit their stride. It’s often not about one big failure, but a complex interplay of subtle factors. Just like inconsistent feedstock disrupts a process, an inconsistent approach to troubleshooting can derail efforts.

My key finding? Applying a structured, data-driven methodology to diagnose performance gaps brings clarity to complexity.

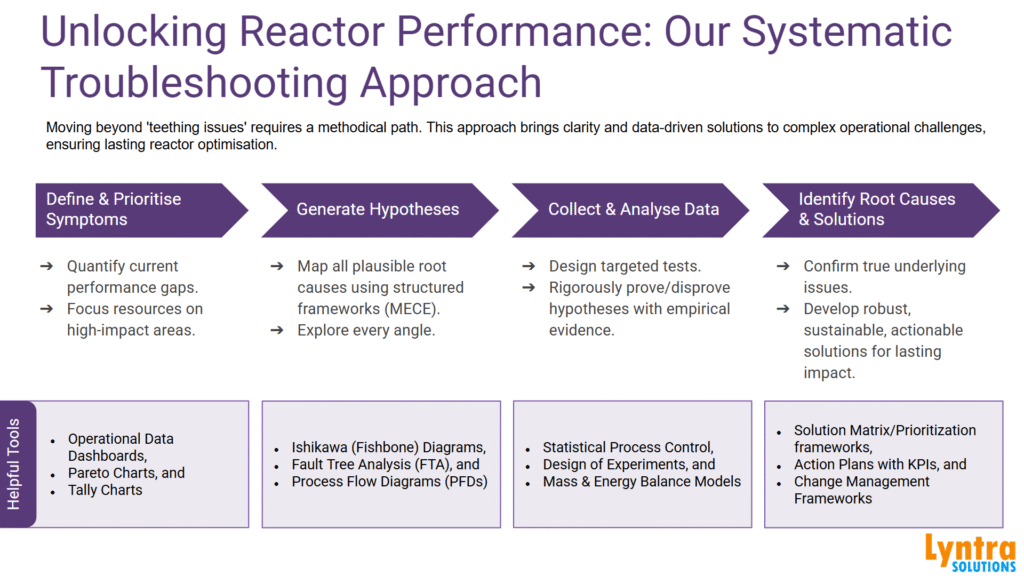

Here’s the systematic approach I use when working with clients to resolve these trickier reactor puzzles:

1. Defining & Prioritising Symptoms: We go beyond ‘it’s not working right.’ We quantify exact deviations – specific yield shortfalls, char inconsistencies, or unexpected energy consumption. Prioritising issues prevents wasted effort.

– Tools: Operational Data Dashboards, Pareto Charts, Tally Charts.

2. Generating Comprehensive Hypotheses: Instead of quick assumptions, we map out every plausible root cause. This breaks down the system (from feedstock in to products out) into components like thermal profile, residence time, mass transfer, and control logic. Structured thinking ensures no stone is left unturned.

– Tools: Ishikawa (Fishbone) Diagrams, Fault Tree Analysis (FTA), detailed Process Flow Diagrams (PFDs).

3. Data Collection & Analysis: This is where we gather evidence. We design targeted investigations – adjusting a single parameter, installing temporary sensors, or conducting specialized material analysis. Then, we rigorously analyse this data to scientifically prove or disprove our hypotheses.

– Tools: Statistical Process Control (SPC), Design of Experiments (DOE), Mass & Energy Balance Models.

4. Root Cause & Solution Development: Once true underlying issues are identified via data, we craft robust, sustainable solutions. The goal is always lasting improvement that enhances reactor efficiency and output, not just a temporary fix.

– Tools: Solution Matrix/Prioritisation frameworks, Action Plans with KPIs, Change Management Frameworks.

A Real-World Example: We once tackled product consistency issues, initially suspecting feedstock. While it contributed, the actual root cause was improperly installed heater bands. Sections had stretched, losing contact, leading to inconsistent heating and premature damage. Fixing this, plus retraining staff on correct installation, achieved desired results and reduced maintenance costs.

This systematic approach isn’t just about problem-solving; it builds resilience and confidence in your bio-energy operations. It shifts the conversation from ‘what’s wrong?’ to ‘how do we consistently achieve optimal performance?’

Unlocking Reactor Performance: Our systematic troubleshooting approach