In Part 1, we covered the robust, human-independent controls: Elimination, Substitution, and Engineering. Now, we move to the final two layers of the safety blueprint, the essential, human-driven protocols that keep those engineered systems effective.

These layers rely on people and discipline. They are the necessary defense when physical barriers fail.

4. Administrative Controls (The System & Discipline)

These are the procedures and training that govern how work is done. They represent a mature safety system and are our last chance to prevent an incident before it physically happens.

– Rigorous Housekeeping: A simple, non-negotiable step. This means scheduled, documented cleaning—especially in hard-to-reach areas. Crucially: NEVER use compressed air, as this disperses the dust and creates an immediate explosion risk. Only use certified ATEX/explosion-proof vacuums.

– Preventive Maintenance (PM): Regularly inspect and lubricate bearings, motors, and conveyors. Friction and overheating are common ignition sources; PM programs prevent them.

– Permit & Procedure Systems: Implement strict Hot Work Permit systems and detailed Safe Operating Procedures (SOPs). Any process or equipment change must go through a formal Management of Change (MOC) review.

– Comprehensive Training: Training must go beyond the basics. All personnel need to understand the science of the hazard, including concepts like MIE (Minimum Ignition Energy) and how to report near-misses (e.g., small dust puffs or hot bearings) without fear.

– Safety Critical Equipment (SCE) Verification: Your engineered systems (like explosion vents or suppression barriers) only work if they are operational. Implement scheduled and documented functional testing for all SCE.

5. Personal Protective Equipment (PPE) (The Last Line of Defense)

PPE is at the base of the pyramid because it only protects the individual after an exposure has already occurred. If you’re relying on PPE, it means the top four controls have failed.

However, when working with combustible dust and high-temperature processes, basic PPE must be upgraded:

– Respiratory Protection: For dust exposure, use the appropriate level of protection, such as N95 or P100 respirators.

– Thermal Protection: Use Flame-Resistant Clothing (FRC) as standard, especially in areas where a dust deflagration is possible. This is critical for preventing severe burn injuries.

The Hierarchy of Controls is not just a diagram; it’s a financial and operational strategy. By prioritizing investment in in 1 – 3, we reduce our long-term reliance on unreliable, human-dependent, and reactive controls like Administration and PPE.

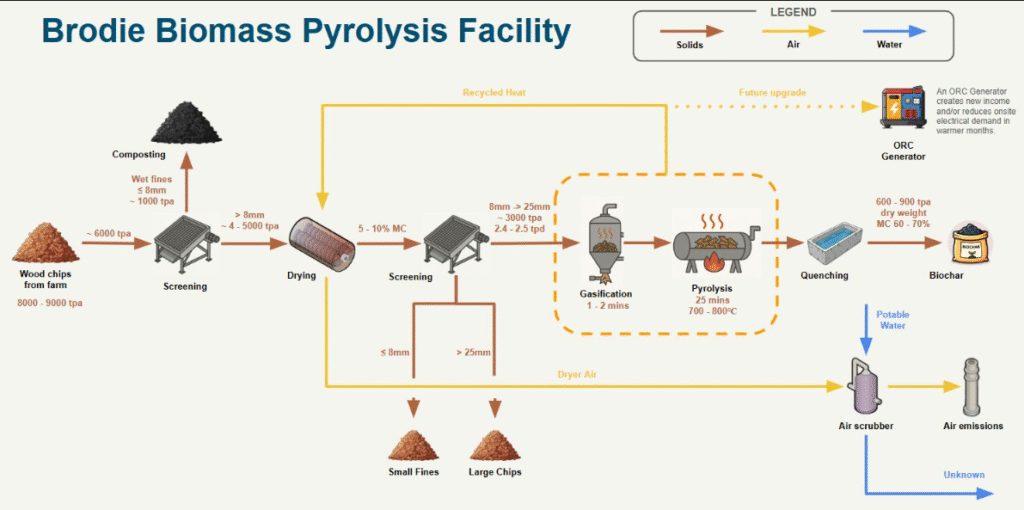

If you’d like the 1 pager applying this framework to biomass pyrolysis dust risks that’s pictured, you can get it from the resources section on this website.

Lyntra

Your Safety Blueprint: The Hierarchy of Controls (Part 2 of 2)