Following up on the excellent questions from our recent post, let’s dive into a crucial, and often misunderstood, aspect of explosions: the difference between a deflagration and a detonation. While both are dangerous, understanding this distinction is key to protecting our facilities.

1. The “Normal” Explosion: Deflagration

As we discussed with the “dust explosion pentagon,” a typical dust explosion is a deflagration.

– What it is: A rapid combustion event where the flame front moves slower than the speed of sound. The pressure builds as hot gases expand.

– The Danger: A deflagration’s pressure wave is destructive, rupturing vessels and blowing out walls. It’s the most common industrial explosion, and the one we typically design protection for.

2. The Catastrophic Event: Detonation

A detonation is a far more severe event.

– What it is: An explosion where the flame front moves at supersonic speeds, propelled by a leading shockwave. The pressure rise is instantaneous and far higher than in a deflagration.

– The Danger: A detonation produces a devastating pressure spike that can shatter equipment designed to withstand normal deflagration pressures.

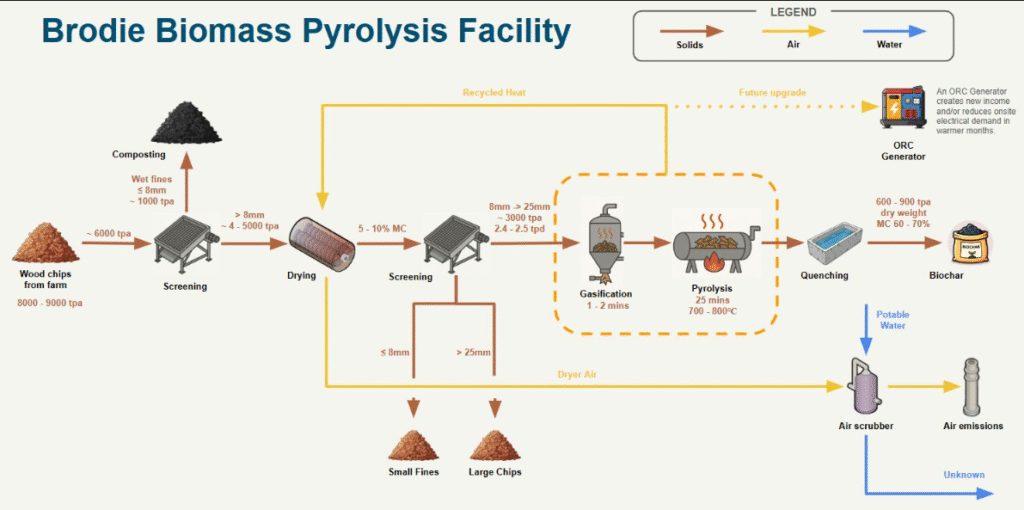

3. The Biomass Pyrolysis Risk: From Deflagration to Detonation (DDT)

This distinction is especially relevant in biomass pyrolysis due to the long, confined spaces in our systems, like ducts, pipes, and conveyor systems.

A deflagration can be the starting point for a Deflagration-to-Detonation Transition (DDT). As the flame travels down a long pipe, obstacles like elbows and valves create turbulence, speeding it up until it breaks the sound barrier and transitions into a full-scale detonation.

4. Mitigating the Ultimate Threat

While our core prevention strategies (dust control, ignition source management) remain the most effective first line of defense, we must consider the potential for DDT in our design and protection protocols.

– Engineering Controls: Ensure your facility’s Hazardous Area Classification (HAC) and equipment ratings are based on a thorough risk assessment.

– Specialised Protection: For high-risk areas consider advanced systems. While explosion vents may work for deflagrations, more robust solutions like suppression systems and flame arrestors are necessary to prevent a high-speed event from propagating.

The takeaway is clear: while we must be vigilant against all forms of dust risk, a comprehensive safety strategy requires understanding the most extreme potential outcomes. A proactive approach in the design phase can be the difference between a manageable incident and a catastrophic failure.

What are your thoughts on assessing and mitigating DDT risk in biomass processing? Share your insights on the engineering and operational controls you’ve found most effective.

Video source: https://lnkd.in/gvCDx7_k

Beyond the Boom: Deflagration vs. Detonation – Why This Distinction is Critical in Biomass Pyrolysis 🔥💥