When it comes to pyrolysis, feedstock isn’t just an input; it’s a critical process parameter.

I’ve just finished watching Christian Wurzer‘s Green Carbon webinar with Brodie Biomass, what a great presentation! Alex Brodie was incredibly honest and forthcoming with information about their process, outputs, and the challenges they faced. I highly recommend checking it out, I’ll share the link in the comments below.

Alex candidly shared that whilst they faced a few challenges early on, none were as detrimental to their utilisation rate as inconsistent feedstock. They had robust biomass screening in place, but some rain caused the screen to became blocked, allowing undersized material into the plant, creating a lot of dust and inconsistent biochar.

A little refresher, any deviation from the optimal feedstock size can directly disrupt the output. The pyrolysis process is finely tuned for a certain particle size, and inconsistency directly impacts the quality and quantity of your biochar, syngas, and pyroligneous acid (vinegar).

Consider the impacts of material that’s:

– Too big:

-> Poor heat transfer due to a lower surface area-to-volume ratio, meaning heat struggles to reach the core. This can lead to incomplete pyrolysis, leaving raw material inside and char on the outside.

-> Slower decomposition, which reduces the yield of valuable gases and pyroligneous acid.

-> Bridging in hoppers, augers, screws, and feed chutes, especially if shapes are irregular or moisture content is high.

– Too small (fines):

-> Dust generation, which can create significant fire and explosion hazards, posing safety risks and operational challenges.

-> Clogging and fouling of equipment, leading to reduced efficiency and increased maintenance.

Generally, inconsistent feedstock of any kind can create non-uniformities in:

– Moisture content: Directly impacts energy balance and product quality.

– Bulk density: Affects how much material can be fed into the reactor and overall throughput.

– Ash and mineral content: Can influence char quality, catalytic reactions, and slagging/fouling.

– Heat profiles within the reactor: Inconsistent feeding and particle size lead to uneven thermal distribution within the reactor, impacting consistency of the product.

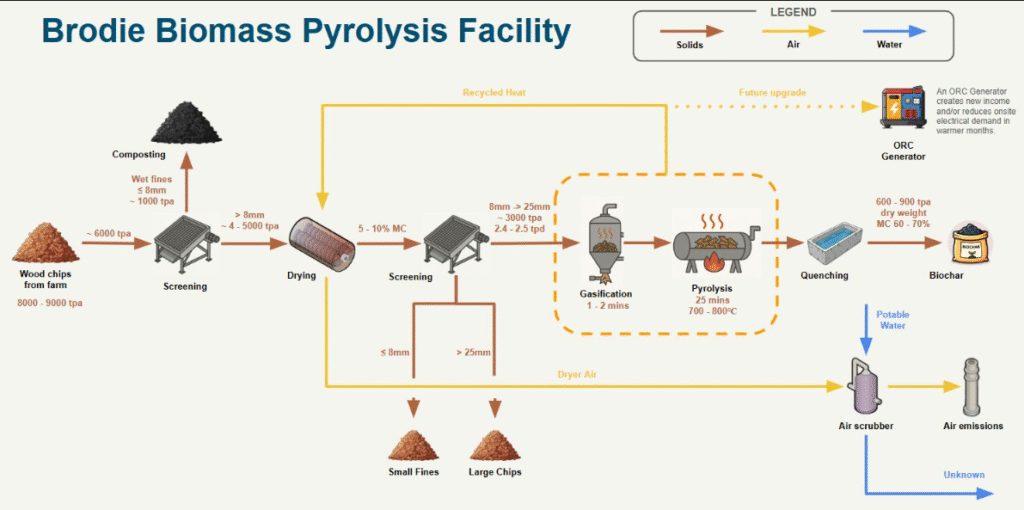

I’ve put a PFD I made using info shared in the presentation of their process, utilising Woodtek Engineering Ltd‘s thermal process. Some interesting takeaways from it, especially their use of a dual-stage pyrolysis system with gasification prior to pyrolysis and then quenching. It’s a different approach that seems to be working really well for Alex’s feedstock and others that have the system installed.

Link to the video