Optimising biomass preprocessing is a critical first step to unlocking the full potential of a pyrolysis unit. Today we are looking at a new study that looks into the GHG impact of wet and dry milling, the results quite interesting. 🧐

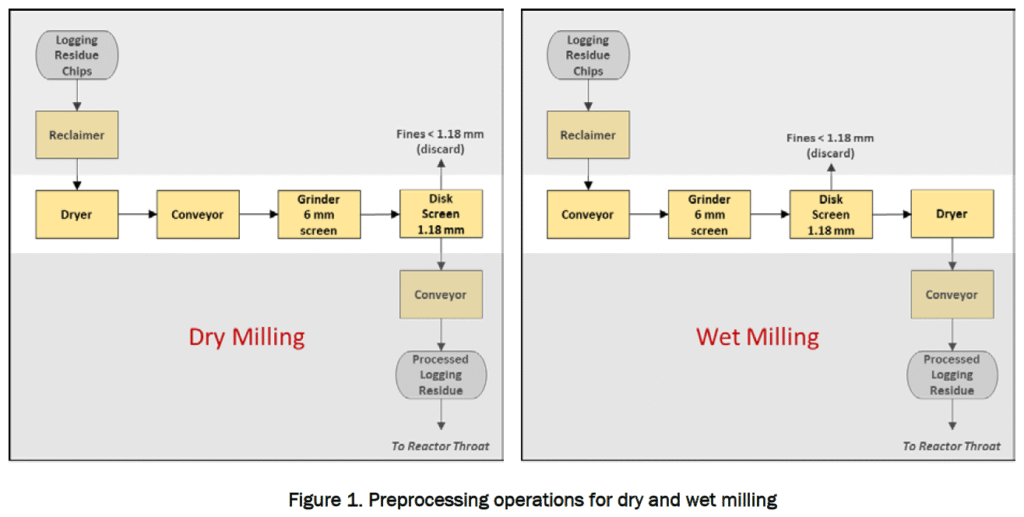

A recent study by Ou et al. (2023), conducted by the Feedstock Conversion Interface Consortium (FCIC) and funded by the U.S. Department of Energy, provides interesting insights. The analysis compared the conventional dry milling process with a wet milling system for forest residues. While the study assumed different unit designs for each process and we aren’t told what unit is used where, the outcomes are intriguing.

The study found that using wet milling for preprocessing resulted in a massive 65% reduction in life-cycle greenhouse gas (GHG) emissions per ton of conversion-ready feedstock compared to dry milling. The bulk of the reduced GHG emissions comes from the reduced energy to dry the product, we’ll go into why this is the case in a follow up post, as well as a reduced amount of loss product. Based on the documented energy savings, an overall reduction in operational expenditure (OPEX) is also a clear implication. A financial model wasn’t part of this initial study, but we will go over a similar study that includes the economics in the near future.

However, it’s not all straightforward. The slurry-like nature of wet-milled biomass can increase the risk of issues like clogging and bridging, making material handling more difficult and potentially leading to increased downtime that could offset these gains. Success is highly system-specific. This is where expertise comes in.

If you’d like a copy of the study, reach out or comment below, and I’ll send it over.

For anyone navigating the complexities of biomass preprocessing for pyrolysis, Lyntra is here to help. We are passionate about helping you design, engineer, and optimise your systems to achieve a better yield and a lower environmental footprint. Let’s work together to build a more sustainable future for bioenergy.