From the science of a dust explosion to the practical controls, we’ve covered a lot. As we close this discussion, here is a final guide for anyone operating a biomass pyrolysis reactor.

Remember these key facts:

– Biochar dust is a major hazard, often more explosive than its feedstock.

– The Hierarchy of Controls is our roadmap for risk mitigation.

– A Dust Hazard Analysis (DHA) is the foundation of your safety plan.

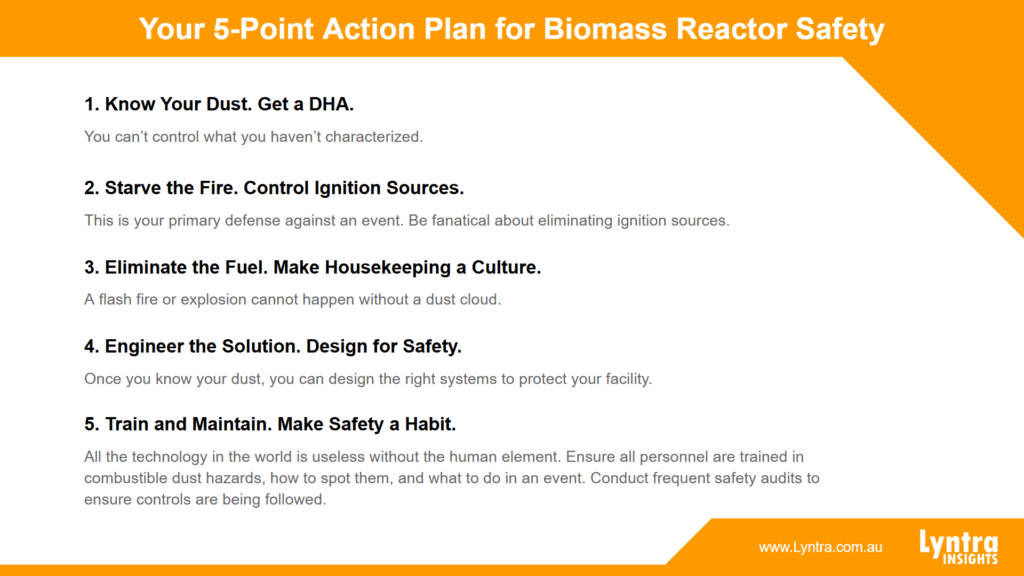

With that, here is a practical, 5-point action plan for assessing and mitigating your risks.

1. Know Your Dust. Get a DHA. You can’t control what you haven’t characterized. Your first action is to get a professional Dust Hazard Analysis.

Get samples tested from every stage of your process, feedstock, biochar, and fines. Use these real numbers for MIE, Kst, and Pmax to inform every other decision.

2. Starve the Fire. Control Ignition Sources. This is your primary defense against an event. Be fanatical about eliminating ignition sources.

– Operator Vigilance: You know your equipment best. During your daily walks, listen for a change in noise or feel for an increase in temperature. A hot bearing or a new grinding sound could be a spark waiting to happen.

– Static Electricity: Ground and bond all equipment.

– Preventive Maintenance: Regularly inspect for friction and electrical faults.

– Foreign Material: Use magnets and metal detectors to remove metal.

– Hot Work: Implement a strict permit system.

3. Eliminate the Fuel. Make Housekeeping a Culture. A flash fire or explosion cannot happen without a dust cloud. Housekeeping is your most effective daily control against this.

– Schedule & Document: Implement a rigorous, scheduled cleaning program.

– Hard-to-Reach Areas: Prioritize cleaning rafters and the tops of all equipment, where the lightest, most dangerous dust settles.

– Use the Right Tools: Use industrial vacuums rated for combustible dust. Never use compressed air.

4. Engineer the Solution. Design for Safety. Once you know your dust, you can design the right systems to protect your facility.

– Local Exhaust Ventilation (LEV): Capture dust at its source.

– Explosion Protection: Install the correct safety equipment based on your DHA. This could include explosion vents to safely release pressure, suppression systems to extinguish an event, or isolation systems to prevent its spread.

5. Train and Maintain. Make Safety a Habit. All the technology in the world is useless without the human element. Ensure all personnel are trained in combustible dust hazards, how to spot them, and what to do in an event. Conduct frequent safety audits to ensure controls are being followed.

It’s about moving beyond compliance and building a culture where everyone understands the risks and their role in mitigating them.

What’s one action you will take this week to improve dust safety at your plant?

Lyntra

The Final Piece: Your 5-Point Action Plan for Biomass Reactor Safety 💥