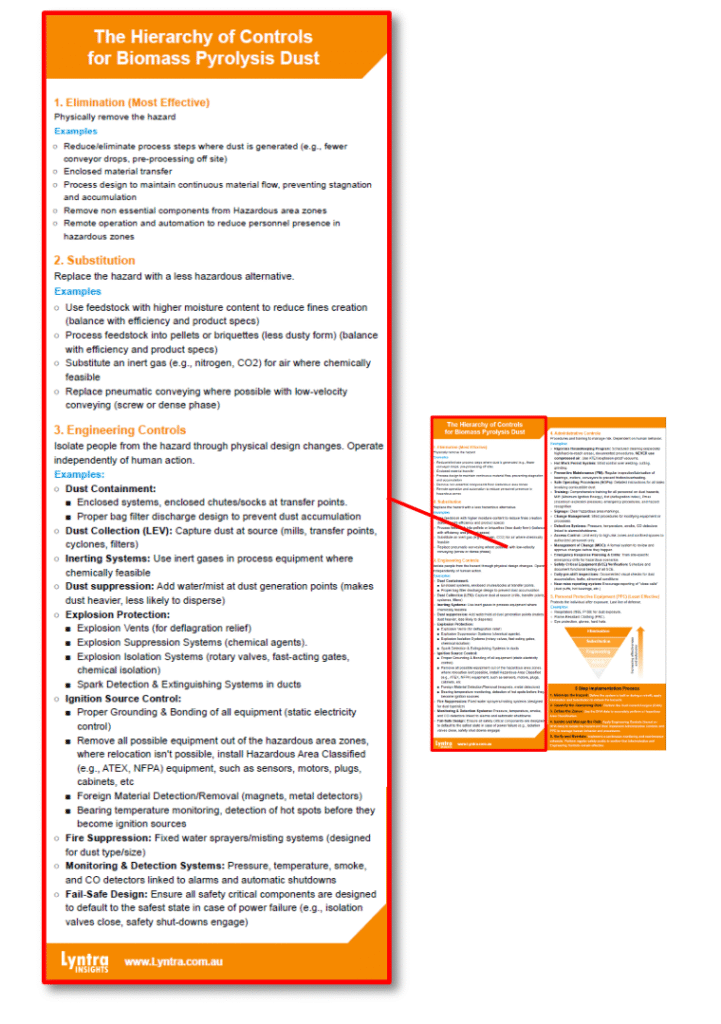

In our last post, we established that biochar presents a greater hazard than its feedstock. Now, let’s explore the most effective framework for managing that risk: The Hierarchy of Controls.

This is the universal blueprint for safety, prioritising the most reliable controls at the top. We’ll apply the most effective levels to biomass pyrolysis dust.

If you’d like the 1 pager applying this framework to biomass pyrolysis dust risks that’s pictured, you can get it from my website (no paywall or sign up) or feel free to reach out either in the comments or in DM.

1. Elimination

This is the most effective control, as it physically removes the hazard. In a biomass process, we can’t eliminate the material itself, but we can design the process to eliminate the hazard of dispersed dust. This includes reducing the number of transfer points (like conveyor drops) where dust is generated and ensuring a continuous, enclosed flow of material.

2. Substitution

This involves replacing a hazardous material with a less hazardous one. While you can’t swap out biomass, you can substitute a less hazardous form of it. Using biomass with a higher moisture content or processing it into pellets can significantly reduce the generation of fine, combustible dust.

3. Engineering Controls

These are physical changes to the plant that isolate people from the hazard. They are our most robust defense and are where the vast majority of our safety budget should be spent. Engineering controls operate independently of human action.

– Process Optimization: Design your milling process to reduce the generation of fines. Screen the material to remove fines as early as possible in the process, and use enclosed “socks” or chutes at all product drop points to contain dust.

– Local Exhaust Ventilation (LEV): Capture dust at every point of transfer, such as conveyor belts and mill exits.

– Specialized Misting/Spraying: Use water sprayers adjusted to the size of your dust particles to suppress airborne dust.

– Explosion Protection Systems: Based on the data from a Dust Hazard Analysis (DHA), install systems like explosion vents to safely release pressure, suppression systems to stop a developing event, or isolation barriers to prevent a deflagration from spreading.

– Grounding & Bonding: Ensure all equipment is properly grounded and bonded to prevent static discharge, a common ignition source.

In the next post, we will cover the final two layers of the pyramid: Administrative Controls and PPE.

After that we’ll wrap up our mini series on dust risks with a 5-step implementation process and a self evaluation checklist you can do to assess your current situration (Not a repalcement for a formal evaluation, but a good starting point).

If you found this information valuable, please share it to help raise awareness of these risks in our industry.

Your Safety Blueprint: The Hierarchy of Controls (Part 1 of 2)