Last week, we explored how in-situ steam acts as a hero in biomass pyrolysis by reforming tars. But what exactly is this “tar” we are trying to reform?

The common misconception is that tar is a single, uniform substance. In reality, it’s a complex and diverse mixture of hundreds of different organic compounds that are an unavoidable byproduct of biomass depolymerization.

The key to effective pyrolysis isn’t to eliminate tar completely but to understand its formation pathways and manage it.

The process begins inside the biomass particle itself. As the biomass is heated, its main components, cellulose, hemicellulose, and lignin, thermally decompose. This is not a single reaction, but a series of complex pathways that yield different products. These radicals initiate follow-on reactions that lead directly to the formation of primary tars. Key among these are free radicals, which initiate follow-on reactions that lead directly to the formation of primary tars.

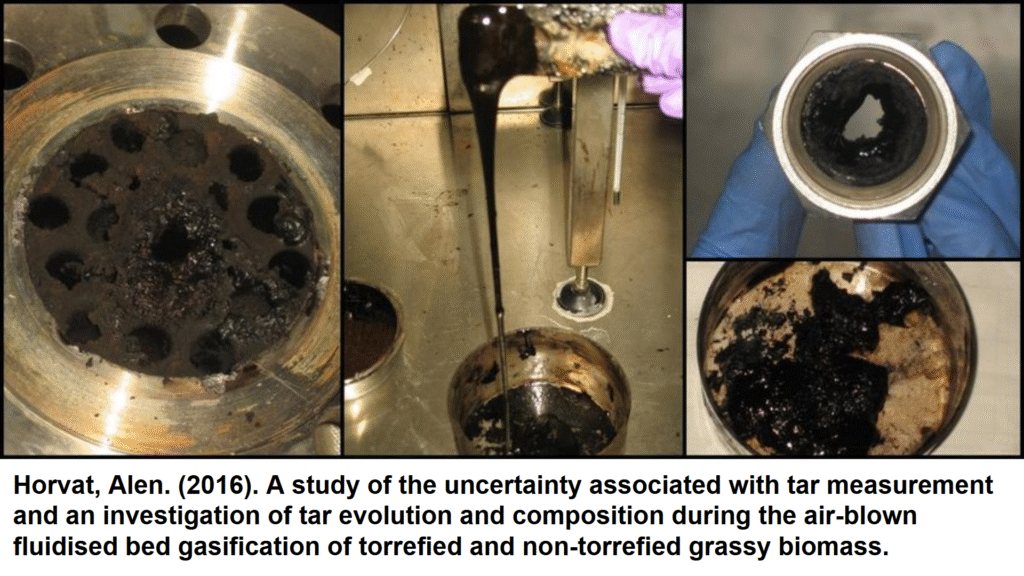

If left unchecked, these tars can undergo secondary reactions as they travel through the hot reactor, leading to repolymerization, condensation, and dehydrogenation. This is where the more problematic, high-molecular-weight tars like polycyclic aromatic hydrocarbons (PAHs) are formed. If given even more time, these PAHs can continue to grow into even larger, more complex molecules.

The Three Stages of Tar

Here’s a breakdown of the three types of tars and their practical impact on your process:

– Primary Tars: These are formed directly from the depolymerization of biomass. They are generally oxygenated compounds like furans and phenols.

– Secondary Tars: These are formed from the cracking and repolymerization of primary tars. These include lighter aromatic hydrocarbons like benzene, toluene, and xylene (BTX), as well as the more problematic PAHs

– Tertiary Tars: These are the heavy, highly stable PAHs that are prone to solidifying and fouling equipment. They are the primary cause of downtime and increased maintenance costs in a pyrolysis reactor.

The Feedstock Connection

The type of tar you get is heavily influenced by your feedstock:

– Cellulose and Hemicellulose-Rich Feedstocks: These tend to produce more oxygenated and lighter primary tars.

– Lignin-Rich Feedstocks: These will yield a higher amount of phenols and other aromatic compounds, which are the building blocks of the problematic heavy tars.

– Tars will always form no matter how well the process is controlled. This is why we need a strategy to handle them and reduce the likelihood that they will transform into heavier, more difficult tars.

Next week, we’ll dive into the specific strategies we can use to break down these tars, focusing on how steam reforming turns these molecular nightmares into a valuable, high-quality syngas.

What is a key lesson you’ve learned about the chemical breakdown of tars in your own work? Share your thoughts below!